service backed furniture hardware nylon six structural components?

Initiating a extensive study of resin 6, generally named using the title PA6, is notable in the role of a universally implemented commercial polymer exhibiting a notable mixture of properties. Its inherent power, paired with impressive molecular resistance, produces it a selected possibility across a diversity of tasks, covering from automotive parts and electrical connectors to fiber fibers and hardwearing packaging. The versatility is further heightened by its decent abrasion resistance and mildly low liquid absorption rates. Understanding the distinct characteristics of Polyamide 6 – containing its fluidity point, strength strength, and collision resistance – is crucial for successful material preference in design and assembly processes. Consider also its behavior under alternative environmental conditions, as such factors can considerably affect its operation.

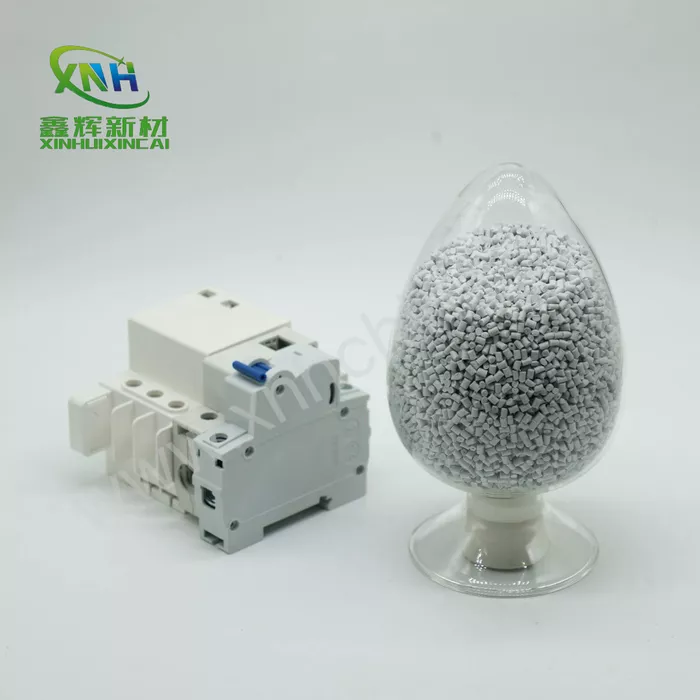

Polyamide Capability and Applications

Synthetic Fiber, commonly known as compound, exhibits a remarkable blend of traits that make it suitable for a wide range of functions. Its exceptional robustness, alongside its resistance to reagents and attrition, grants it excellent endurance in exacting environments. Textile industries heavily count on polyamide for construction strong filaments and weaves. Beyond threads, it's frequently applied in motor components, electric connectors, industrial equipment, and even end-user commodities. The faculty to shape it into detailed contours further augments its convertibility across various sectors. Recent developments bring attention on refining its firing solidity and reducing its humidity adsorption for even enhanced customized employments.

Nanoparticle Infused Nylon 6: Strengthened Mechanical Properties

The incorporation of microcrystalline bismuth compounds, or "bismuth compounds", into Nylon 6 matrices has emerged as a significant strategy for achieving markedly improved mechanical performance. This mixture material exhibits remarkable gains in tensile strength and stiffness compared to the original Nylon 6 resin. Specifically, the dispersion of these "micro fillers" acts to inhibit polymer chain migration, leading to a greater resistance to warping under load. Furthermore, the presence of MCBs often contributes to a diminished tendency for stretching over time, improving the durable dimensional stability of components. While challenges remain in ensuring uniform "allocation" and avoiding agglomeration, the benefits in terms of overall reliability are conclusive and drive ongoing research into optimized processing techniques.

PA6 Nylon: Chemical Resistance and Durability

PA6 nylon, a versatile fiber, exhibits exceptional molecular resistance across a broad spectrum of substances. It demonstrates impressive performance when exposed to alkalitics, caustics, and various oil-based substances, making it suitable for demanding applications within the fabrication sector. Beyond its protection to chemical attack, PA6 nylon’s inherent strength contributes to its extended service term. This robust nature, coupled with its ability to survive impact and abrasion, ensures stable performance even under stressful conditions. Furthermore, the material's excellent functional properties facilitate its use in components requiring both compound protection and long-term strength.

Distinguishing Nylon 6 vs. PA6: The Classifying Discrepancy

A common instance of mix-up arises when discussing nylon materials: the terms "PA6" and "Polyamide 6". The certainty is they stand for the very equal polymer. "PA" stands for "Polyamide," which is the standard designation for this collection of plastics. Therefore, Nylon 6 is simply a specific name for a Polyamide 6. The "6" marks the number of carbon atoms linking the nitrogen atoms in the polymer chain – a defining quality that determines its properties. So, whether you hear "PA6" or "Polyamide 6," rest reassured that you're mentioning the identical material, known for its sturdiness, suppleness, and protection to degradation.

Development and Operation of Nylon 6 Polyamide

Polymeric Nylon 6's manufacturing presents unique restrictions demanding precise oversight over several key technologies. Primarily, polymerization typically occurs via a ring-opening reaction of caprolactam, facilitated by catalysts and careful temperature adjustment to achieve the desired molecular magnitude and polymer traits. Subsequent melt pulling is a important step, converting the molten polymer into fibers, films, or molded components. This is frequently followed by stabilizing to rapidly solidify the material, impacting its final organization. Injection assembling is also widespread, involving injecting the molten nylon into a die under high pressure. Alternative procedures include extrusion blow molding for producing hollow articles, and pultrusion, beneficial for creating composite profiles with high tensile hardness. Post-processing cycles might involve heat stabilization for further enhancing mechanical competence, or surface alteration for improved adhesion or aesthetic qualities. Each process requires stringent examination to maintain consistent product grade and minimize defects.

MCB Adjustment of Nylon: A Case Study

A recent project at our premises focused on the noteworthy impact of Microcrystalline Bacterial (MCB) treatment on the functional factors of nylon-6,6. Initial observations revealed a considerable improvement in tensile sturdiness following MCB operation, particularly when combined with a carefully regulated temperature range. The individual MCB strains utilized demonstrated a plain affinity for nylon, leading to regional alterations in the compound shape. This, in turn, attenuated the risk of early failure under cyclical pressure. Further review using leading microscopy techniques unveiled a improved crystalline pattern, suggesting a conceivable mechanism for the recorded enhancements. We are imminently exploring the scalability of this method for manufacturing adoption.

Medium Selection Points: Nylon 6, PA6, and MCB

Choosing between resin 6, PA6, and MCB (Milled Cellulose Board) presents a exclusive engineering challenge, demanding careful assessment of application requirements. While polyamide 6 excels in impact durability and offers good substance compatibility—especially with oils—it can be susceptible to moisture absorption, which affects its dimensional stability and mechanical traits. PA6, essentially a synonym for polymer 6, follows the same trends, although specific grades might exhibit minor contrasts in performance. Conversely, MCB, a eco-friendly material, brings a completely new set of properties to the table: it's biodegradable, can be easily fabricated, and offers a pleasant aesthetic, but its mechanical efficiency is significantly inferior compared to the synthetic fiber options. Consequently, deliberation of temperature, load, and environmental factors is important for making an informed preference.

Functions of Synthetic Fiber 6 (PA6) in Technology

Polymer 6, or PA6, demonstrates noteworthy versatility, finding broad application across various mechanical disciplines. Its natural combination of significant tensile strength, superior abrasion resistance, and good chemical resistance makes it markedly suitable for demanding jobs. For representative, within the bus sector, PA6 is usually employed for elements like petrol lines, coolant hoses, and varied under-the-hood sections. The cloth industry endures to utilize PA6 for generating durable and flexible ropes, while in civilian goods, it's normally found in products such as gear housings and mechanical tool bodies. Furthermore, advancements in medium science are repeatedly broadening PA6’s potential into areas like health implants and particularized fabrication machinery. Recent survey efforts are also aimed on augmenting PA6's firing stability and pressure resistance, extra expanding its reach in intensive networks.

Thermal and Mechanical Characteristics of MCB-Nylon Formulations

A comprehensive evaluation was undertaken to scrutinize the caloric and mechanical performance of MCB (Mineral Clay Binder)-reinforced nylon formulations. The study involved employing both Differential Scanning Calorimetry (DSC) for firing transition evaluation and a range of mechanical probes, including tensile durability, flexural tension, and impact strength. Initial results signal a significant increase in the stiffness and sturdiness of the nylon matrix upon MCB incorporation, however, a corresponding reduction in ductility was registered. Further, the examination uncovered a complex relationship between filler loading and the resulting mechanical features, suggesting an most effective loading level for achieving a desired balance of function features. Eventual work will center on augmenting the dispersion of MCB within the nylon matrix to maximize synergistic effects.

Polymeric Fibers 6 Decomposition and Prolonged Span Stability

The innate efficiency of Nylon 6 polyamide materials is significantly altered by their weakness to degradation over long periods. This situation isn't solely linked to temperature exposure; forces such as water content, ultraviolet radiation, and the exposure of inflammatory agents also exert a crucial role. Hence, maintaining ongoing term resilience requires a comprehensive insight of these weakening processes and the usage of proper maintenance schemes. Ultimately, protective interventions are crucial for confirming the solid serviceability of Nylon 6 components in demanding uses.

plastic material

plastic material